About Us

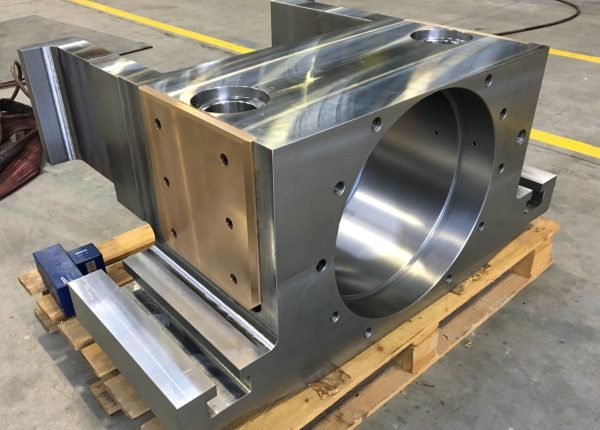

In 2012, it expanded its premises with a total closed area of 3.500 m², and over the years, it has commissioned two more Dual Track Induction Furnaces, each with a capacity of 1.500 kg, a total of 3.000 kg. Our company, which has the capacity to produce castings from 1 kg to 3,000 kg as unicast, has expanded its product range up to 3,000 tons per year.

Production and Quality

Core Unit The cores of casting products, manufactured in our factory through cold box, hot box and shell core methods, are dried in the core drying oven to meet the highest quality standards and are given to the production line after passing the necessary quality controls.

Quality Control Our company, which always adopts customer satisfaction as a principle in its quality policy, attempts to manufacture products under customer demands and offer them on time. Products’ quality control is always under control before and after production. We know the importance of our quality control phrases and apply them to determine product specifications, … Continue reading Quality Control

Sandblasting We carry out the sandblasting process of the casting parts, which are taken from the shakeout machine and still have sand, with two sandblasting machines we have within our structure. The parts taken from the Shakeout Machine are properly placed in specially prepared high manganese baskets and the lids are closed. The process is … Continue reading Sandblasting

NORMALIZING (HEAT TREATMENT-ANNEALING) The purpose of the normalizing process is to gain the steel a homogeneous/uniform and fine-grained structure. The process is applied to obtain a predictable microstructure and an assurance of the steel’s mechanical properties. Advantage After forging, hot rolling, or casting, the microstructure of the steel becomes coarse-grained and non-homogenized and consists of … Continue reading NORMALIZING (HEAT TREATMENT-ANNEALING)

Why BİRLEŞİM DÖKÜM

For 36 years, we have been working with the same excitement and determination as on the first day.